Quality Policy / Processes

We manufacture our products from excellent quality raw materials so as to guarantee our customers of the quality of our products. All our products are passed through stringent quality checks, which further mark our products as reliable and authentic.

NOTE: We also give lab testing report of customer requirements.

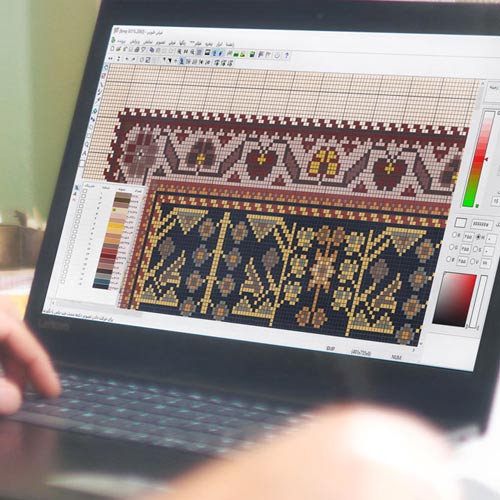

Designing and conceptualization

When speaking of design and conceptualization skill and a thought process comes into play. Our team of designers are experienced enough as per the market requirements as well skilled to translate customer requirements into bespoke products be they are oriental, traditional, modern, geometric, floral designs.

Selection of yarn

The quality, texture and design of a carpet largely depend on the property of the fiber it is made. The principal fibers used in modern commercial carpet manufacturing are wool, silk, bamboo silk, artificial silk, tencel, PET, viscose, etc. and a mix of these. Our yarn selection is an intricate process employing an ideal choice depending upon the customer requirement.

Spinning

Next phase is to spin the selected yarn into the required thickness, number of plies and texture so as to meet specific customer and market requirements. Our in house processes employs dedicated and skilled weavers apt in the trade.

Dying

When the yarn is spun the next phase is to color it. This is a complicated process which demands and knowledge and accuracy. Our inhouse process start with selection of right color from a standardized reference system and ends with dying furnaces. Normally, natural colors are preferred, however synthetic colors can also be used to achieve best results.

Weaving

Weaving carpets require definite skills and a certain level of expertise on the part of the weaver. There have been different types of weaving techniques that can be used to produce carpets with a variety of effects and designs on them. Every act of weaving involves choosing a particular fiber, deciding on colors, imagining an abstract or design, a weaving technique, and finally a finishing process where the carpet finally turns into a refined piece of craft and comfort.

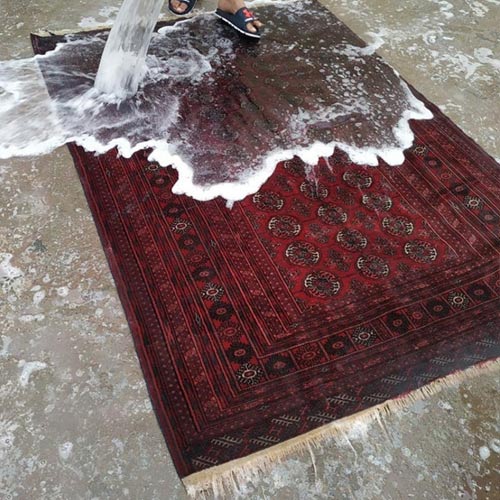

Washing

The carpet is washed for the final time. Final washing provides it the required luster.

Clipping and finishing

This is the finishing step in the manufacturing of carpet. The clipping is done with minute detailing.